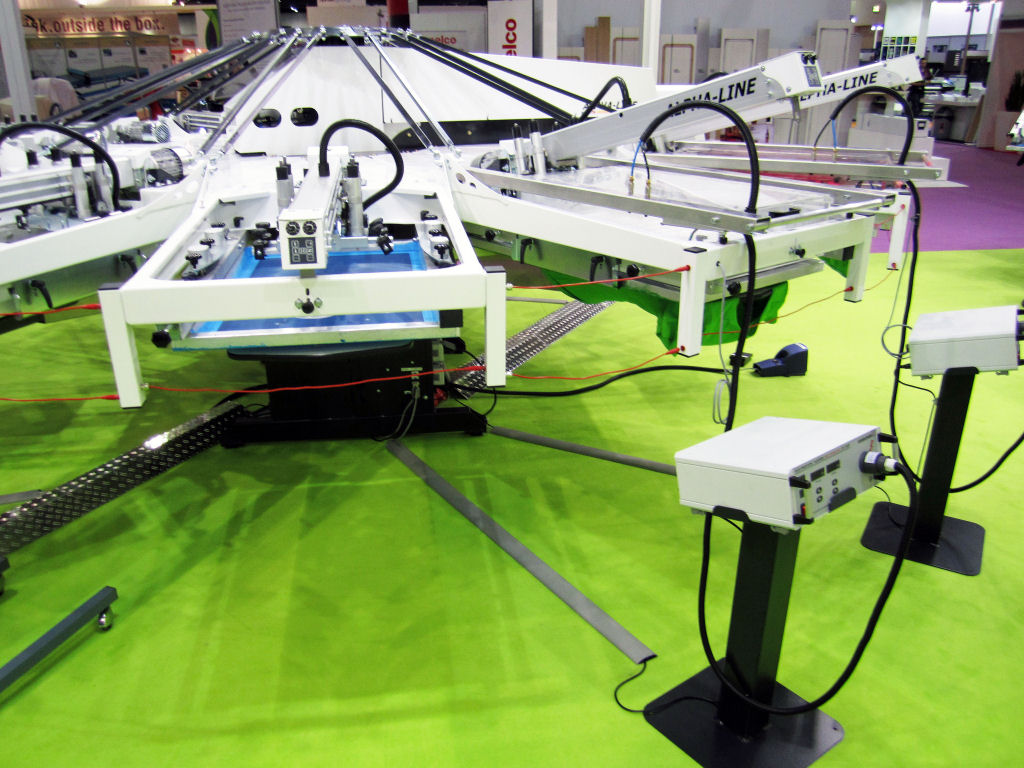

ALPHA-LINE+FLOCK Flocking Machines

- print area max.: 530x700 mm

- flock-area max.: 400x500 mm

- number of stations/pallets: 8-20

- number of printing heads: up to 18

- number of print/flockheads: 1-6

Technical Data

Squeegee-System

- AC-Servo-drive

- high-precision-spindle-drive

- 4-Cylinder POWER-Squeegee-System

- Print/Floodbars with mecanical way-adjustment for precise hight-leveling

- Comfort-liftable print-cylinders

Supporting-arms/pallets

- With fast-snap tensioning-system

- Pallets slideable in lengthwise direction +/- 10 cm

Pallet-drive

- Precise gear-drive, frequency controlled AC-Servo-motor

Flock-System

- high voltage from 10 - 80 kV adjustable

- with ground surveillance

- digital kV- and uA-measuring devices

- automatic high voltage discharge

- dosing time and flock time adjustable

Central Main-Control with SMART- touch-screen Monitor

- with Siemens-standard-modules,

- microprocessor with diagnostic programm - easy to operate –

- control-keypads at every print station for fast set-up START, STOP, LIFT-UP/DOWN, Squeegee-movement Squeegee-stroke-speed individual adjustable

- prepared for permanent-spray-system

- central electronic off-contact adjustable on the touch-screen

Printing programmes

- 6-standard print programs + high density+cool-stop

- + sampling-start up - finishing programs+double-index+Multilap-program

- cleaning-program: in-between pallet-stop, left / right, free wheel-mode

Pictures

Downloads

- About the flocking process

Get more information about the flocking process in detail (PDF file; 299 KB) - Multicolour Flock Flyer

Download our flyer with useful information about our multicolour flock systems (PDF file; 807 KB) - SIEMENS TOUCH Flyer

The machine is controlled by a touch screen based on SIEMENS technology (PDF file; 329 KB)